Safe Manual Handling Techniques in Stock Management

Posted by SkillMaker in Jan, 2025

What is a concise description of safe manual handling techniques when receiving, storing and maintaining stock?

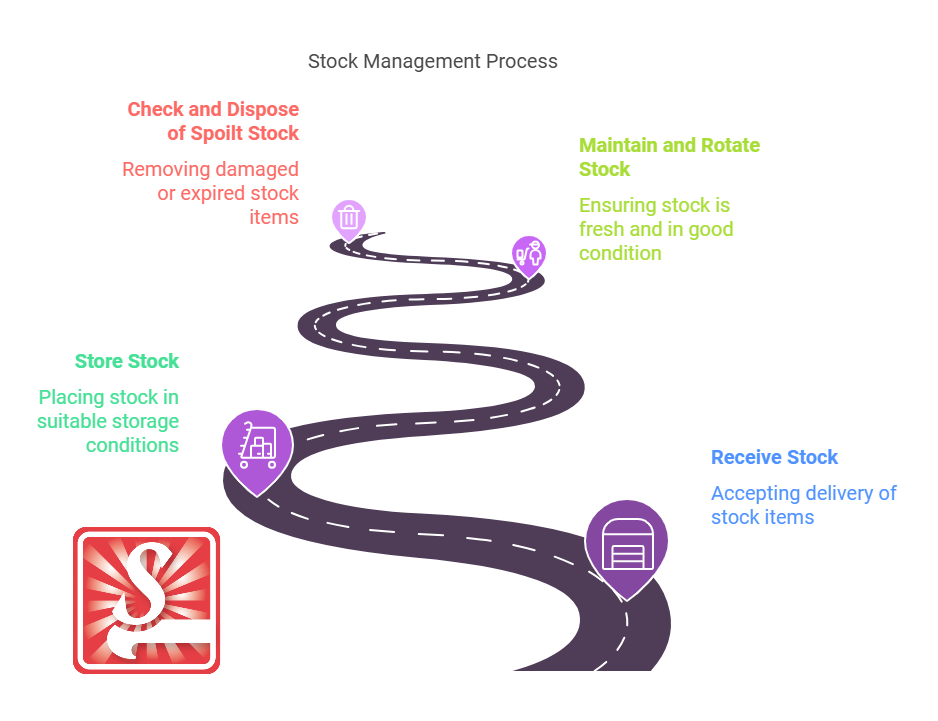

Safe manual handling techniques in stock management involve using appropriate methods and tools to efficiently and safely lift, move, and store materials. This ensures the protection of workers’ physical well-being while maintaining the integrity of stock, thus enhancing productivity and reducing injury-related risks.

Why do people in enterprises need safe manual handling techniques in stock management?

Enterprises need safe manual handling techniques to safeguard their employees from physical injuries, such as strains and sprains, which are common in stock-related tasks. Implementing these practices not only reduces potential work-related injuries and associated costs but also promotes a more efficient workflow, reducing downtime caused by mishandling stock.

“Effective manual handling strategies not only protect workers but also ensure business efficiency by minimizing injury risks and maintaining smooth operations.”

What are the key components or elements of safe manual handling techniques in stock management?

Key components include:

- Assessment: Evaluating the weight, size, and shape of stock before handling.

- Body Mechanics: Utilizing proper lifting techniques such as bending the knees and keeping the back straight.

- Aids and Equipment: Using tools like trolleys, forklifts, or pallet jacks to assist in moving stock.

- Training: Ensuring employees are educated on safe handling practices and risks involved.

- Organisation: Structuring the storage to minimize the need for awkward movements or lifting.

What key terms, with descriptions, relate to safe manual handling techniques in stock management?

Registered Trademark®

- Ergonomics: Designing tasks and tools to best fit the handler’s capabilities to reduce strain.

- Risk Assessment: Process of determining the potential hazards associated with manual tasks.

- Load Management: Properly distributing weight and materials to prevent overexertion.

- Safe Lifting Zone: The area between the knees and shoulders where lifting is safest.

- Musculoskeletal Disorder (MSD): Injuries affecting muscles, nerves, blood vessels, and ligaments caused by improper handling.

Who is typically engaged with operating or implementing safe manual handling in stock management?

Warehouse managers, stock controllers, and inventory staff are mainly responsible for implementing safe manual handling practices. Safety officers and HR personnel may also play vital roles in training and ensuring compliance with safety regulations across the workplace.

How does safe manual handling align or integrate with other components of Hospitality and Catering?

Safe manual handling is vital in Hospitality and Catering, ensuring that employees efficiently manage stock with minimal risk, aligning with areas such as kitchen operations and guest services, where time efficiency and safe work environments directly impact service quality and customer satisfaction.

Where can the student go to find out more information about safe manual handling techniques in stock management?

What job roles would be knowledgeable about safe manual handling techniques in stock management?

Roles include:

- Warehouse Managers

- Inventory Controllers

- Delivery Drivers

- Safety Officers

- Logistics Coordinators

What are safe manual handling techniques like in relation to sports, family, or schools?

In sports, safe manual handling is akin to a player maintaining proper form during training to prevent injury. Within a family setting, it reflects teaching children the importance of posture and lifting techniques when carrying groceries.

In schools, it resembles training on the importance of ergonomic setups to prevent strain from carrying heavy backpacks or books.

(The first edition of this post was generated by AI to provide affordable education and insights to a learner-hungry world. The author will edit, endorse, and update it with additional rich learning content.)

Post Tagged with

Post Tagged with