Understanding Material Costs in Basic Estimation and Costing

Posted by SkillMaker in Jan, 2025

What is a concise description of material costs in basic estimation and costing?

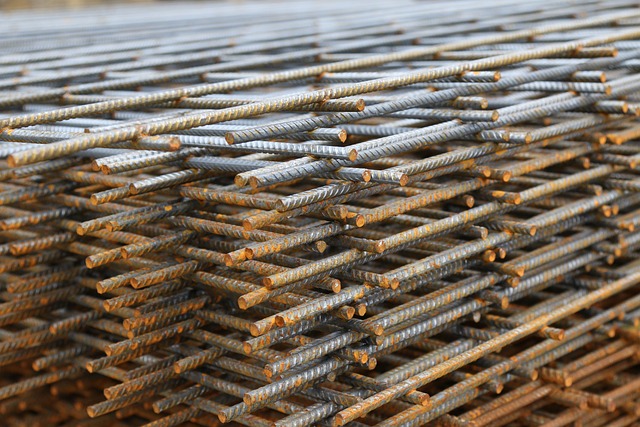

Material costs in basic estimation and costing refer to the expenses related to acquiring all necessary raw materials and supplies for a construction project. These costs are a significant portion of the project’s total budget and must be accurately calculated to ensure the project’s feasibility and profitability.

Why do people in enterprises need to understand material costs in basic estimation and costing?

Enterprises must understand material costs to prepare accurate budgets and bids for construction projects. Thorough knowledge of material costs enables effective resource allocation, helps in avoiding budget overruns, and ensures competitive pricing in tender submissions. Understanding these costs also enhances project planning and supply chain management, leading to improved business outcomes.

“Accurate estimation of material costs ensures financial success and project efficiency in the construction industry.”

What are the key components or elements of material costs in basic estimation and costing?

Key components of material costs include:

- Material Prices: Current market rates for materials needed.

- Quantity Estimates: Accurate measurements of required materials.

- Waste and Allowances: Consideration for waste and potential unforeseen needs.

- Supplier Negotiations: Deals and discounts that impact material costs.

- Delivery and Handling: Costs associated with transporting materials to site.

What key terms, with descriptions, relate to material costs in basic estimation and costing?

Registered Trademark®

- Bill of Quantities (BoQ): A detailed statement listing the quantities of materials required.

- Cost Indexing: Adjusting material costs based on inflation and market trends.

- Procurement: The process of sourcing and acquiring materials.

- Logistics Management: Coordination of material storage and transport logistics.

Who is typically engaged with operating or implementing material costs in basic estimation and costing?

Quantity surveyors, project managers, procurement officers, and estimators are typically engaged in managing and implementing material costs. They collaborate with suppliers to secure materials at optimal prices, ensure materials meet project specifications, and track costs against the budget.

How do material costs in basic estimation and costing align or integrate with other components of Construction in Australia?

Material costs are closely integrated with project scheduling, labour costs, and overall financial management in construction. Accurate estimation of material costs helps in creating realistic timelines, ensuring adequate workforce allocation, and maintaining profitability. This integration contributes to streamlined project execution and enhanced client satisfaction.

Where can the student go to find out more information about material costs in basic estimation and costing?

What job roles would be knowledgeable about material costs in basic estimation and costing?

Roles include:

- Quantity Surveyors

- Estimators

- Cost Engineers

- Project Managers

- Procurement Officers

What are material costs in basic estimation and costing similar to in relation to sports, family or schools?

In sports, material costs are like budgeting for equipment and resources required by a team to perform optimally. In a family setting, it reflects the planning and purchasing of groceries and household items within a budget. In schools, it aligns with managing financial resources to acquire educational materials that facilitate learning and development.

(The first edition of this post was generated by AI to provide affordable education and insights to a learner-hungry world. The author will edit, endorse, and update it with additional rich learning content.)

()

Post Tagged with

Post Tagged with