Storage Area Cleanliness in Receiving, Storing, and Maintaining Stock

Posted by SkillMaker in Jan, 2025

What is a concise description of storage area cleanliness in receiving, storing, and maintaining stock?

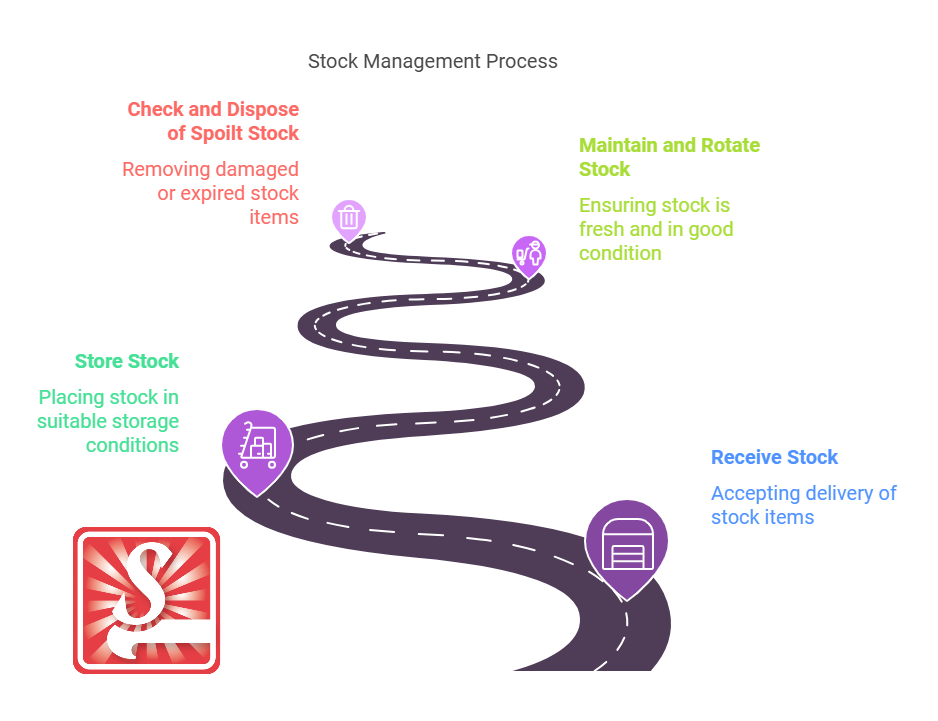

Storage area cleanliness involves ensuring a hygienic and well-organized space for stock to be received, stored, and continuously maintained. This process reduces contamination risks, enhances efficiency, safeguards stock integrity, and supports compliance with health and safety standards.

Why do people in enterprises need storage area cleanliness when receiving, storing, and maintaining stock?

Enterprises require storage area cleanliness to protect stock quality, prevent spoilage or contamination, and adhere to safety regulations. Maintaining a clean environment optimizes handling efficiency, reduces waste, and ensures customer satisfaction by delivering safe, well-kept products.

“Clean storage areas are the cornerstone of effective stock management, guaranteeing product quality and customer trust.”

What are the key components or elements of storage area cleanliness in receiving, storing, and maintaining stock?

Essential components of maintaining cleanliness in storage areas include:

- Regular Cleaning Schedules: Implementing routine cleaning activities to maintain hygiene.

- Organisation Systems: Structuring shelving and storage to minimize clutter and optimize access.

- Pest Control Measures: Preventive actions to deter infestations that compromise stock safety.

- Temperature and Humidity Controls: Ensuring environmental conditions that preserve product integrity.

- Proper Waste Management: Timely disposal of waste to avoid contamination risks.

What key terms, with descriptions, relate to storage area cleanliness in receiving, storing, and maintaining stock?

Registered Trademark®

- Sanitation Protocols: Procedures established to maintain cleanliness and hygiene in storage areas.

- Cross-Contamination Prevention: Processes put in place to avoid the transfer of contaminants between products.

- Inventory Cycle Counts: Regular audits to ensure stock levels match records, supporting orderly storage.

- Material Handling Equipment: Tools and machines used to safely move and store stock, upholding cleanliness by minimizing physical contact.

- Ventilation Systems: Infrastructure that maintains air quality and reduces moisture build-up, essential for cleanliness.

Who is typically engaged with operating or implementing storage area cleanliness in receiving, storing, and maintaining stock?

Warehouse managers, inventory officers, and stock controllers are typically responsible for implementing storage area cleanliness. These roles ensure that all cleanliness protocols are enforced and that areas remain conducive to effective stock management.

How does storage area cleanliness align or integrate with other components of Hospitality and Catering?

Storage area cleanliness aligns with broader Hospitality and Catering operations by ensuring that food safety standards are maintained, contributing to the overall customer experience, and optimizing kitchen and service efficiency. Clean storage practices reduce likelihoods of foodborne illnesses, ensuring quality service delivery.

Where can the student go to find out more information about storage area cleanliness?

- Australian Food Standards

- Department of Health – Environmental Health

- Business.gov.au – Kitchen Standards

What job roles would be knowledgeable about storage area cleanliness?

Roles include:

- Inventory Managers

- Stock Coordinators

- Food Safety Officers

- Warehouse Supervisors

- Hygiene Inspectors

What is storage area cleanliness like in relation to sports, family, or schools?

In sports, storage area cleanliness resembles a well-maintained locker room where equipment is stored hygienically and organized.

For families, it can be compared to keeping a pantry organized and free from pests, ensuring food safety.

In schools, it reflects orderly classrooms where supplies are stored in a clean and systematic manner, aiding in efficient learning environments.

(The first edition of this post was generated by AI to provide affordable education and insights to a learner-hungry world. The author will edit, endorse, and update it with additional rich learning content.)

Post Tagged with

Post Tagged with