Managing Stock Deficiencies in Hospitality and Catering

Posted by SkillMaker in Jan, 2025

What is a concise description of stock deficiencies in receiving, storing, and maintaining stock?

Stock deficiencies refer to the lack of adequate stock levels due to errors or inefficiencies in processes of receiving, storing, or maintaining items. These deficiencies can disrupt operations, lead to dissatisfied customers, and cause financial losses in the hospitality and catering sectors.

Why do people in enterprises need to be aware of stock deficiencies in receiving, storing, and maintaining stock?

Avoiding stock deficiencies is critical for uninterrupted operations, especially in hospitality and catering where customer satisfaction is key. Being aware of stock deficiencies helps businesses minimize lost sales, prevent spoilage, manage budget effectively, and maintain satisfactory service levels.

“Proactively managing stock deficiencies ensures smooth operations and customer satisfaction, fostering trust and reliability in service.”

What are the key components or elements of managing stock deficiencies?

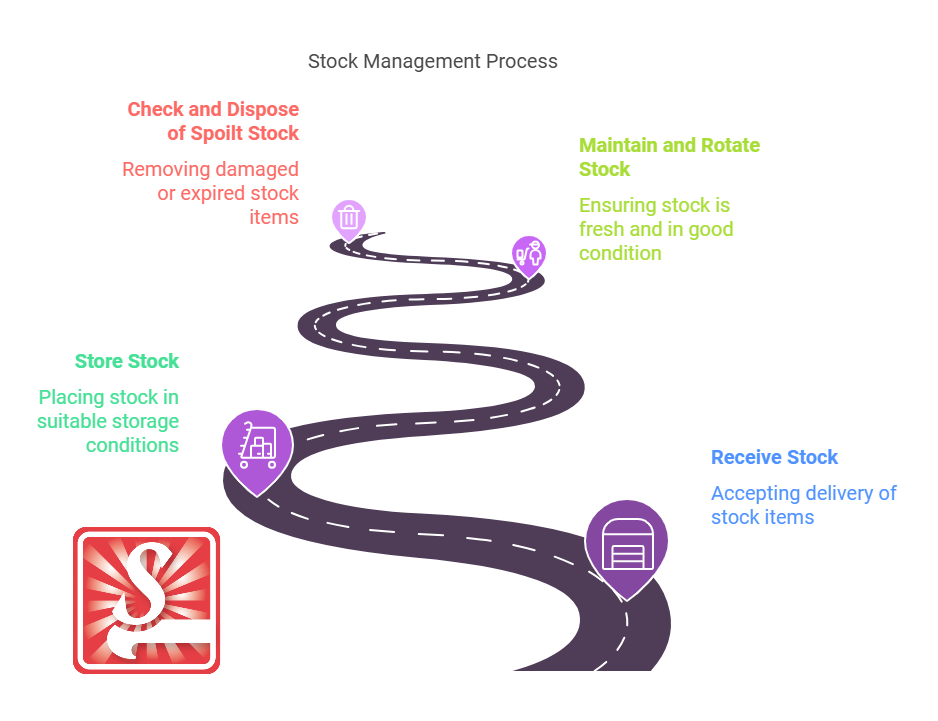

Key components of managing stock deficiencies include:

- Accurate Inventory Management: Regularly updating inventory data to reflect the actual stock.

- Efficient Receiving Processes: Correctly checking deliveries against orders to avoid discrepancies.

- Proper Storage Solutions: Ensuring stock is stored appropriately to prevent damage or spoilage.

- Regular Audits: Periodic checks to identify and address stock discrepancies promptly.

- Training Staff: Training staff in inventory handling and management to enhance accuracy and efficiency.

What key terms, with descriptions, relate to stock deficiencies in receiving, storing, and maintaining stock?

Registered Trademark®

- Stocktake: A process of counting and verifying the entire inventory to ensure records match physical stock.

- Reorder Level: The stock level at which new inventory must be ordered to avoid shortages.

- Backorder: An order that cannot be filled when presented, possibly due to stock deficiencies.

- Shrinkage: Loss of inventory due to theft, damage, or mismanagement.

- FIFO (First In, First Out): An inventory management method ensuring older stock is used first to minimise waste.

Who is typically engaged with operating or managing stock deficiencies?

Roles involved in managing stock deficiencies include inventory managers, warehouse supervisors, procurement officers, kitchen staff in hospitality outlets, and any personnel responsible for ordering and handling stock.

How do stock deficiencies in receiving, storing, and maintaining stock align or integrate with other components of Hospitality and Catering?

Efficient stock management is integral to maintaining kitchen operations, ensuring menu consistency, and minimizing waste. It aligns with overall business operations in hospitality by optimizing costs, improving service delivery, and supporting sustainability initiatives.

Where can the student go to find out more information about managing stock deficiencies?

- Food Innovation Australia Ltd for resource and networking

- Restaurant and Catering Australia for hospitality industry insights

- Australian Institute of Food Science and Technology Industry guidelines

What job roles would be knowledgeable about stock deficiencies in receiving, storing, and maintaining stock?

Roles include:

- Inventory Managers

- Warehouse Supervisors

- Procurement Officers

- Kitchen Staff

- Restaurant Managers

What is managing stock deficiencies like in relation to sports, family, or schools?

Managing stock deficiencies is like a coach ensuring a sports team has the right equipment and resources for every practice and game. In a family, it reflects the careful management of household essentials to avoid running out. In schools, it’s similar to keeping educational supplies in check to support learning activities effectively.

(The first edition of this post was generated by AI to provide affordable education and insights to a learner-hungry world. The author will edit, endorse, and update it with additional rich learning content.)

Post Tagged with

Post Tagged with