Managing Damaged Items When Receiving, Storing and Maintaining Stock

Posted by SkillMaker in Jan, 2025

What is a concise description of managing damaged items when receiving, storing and maintaining stock?

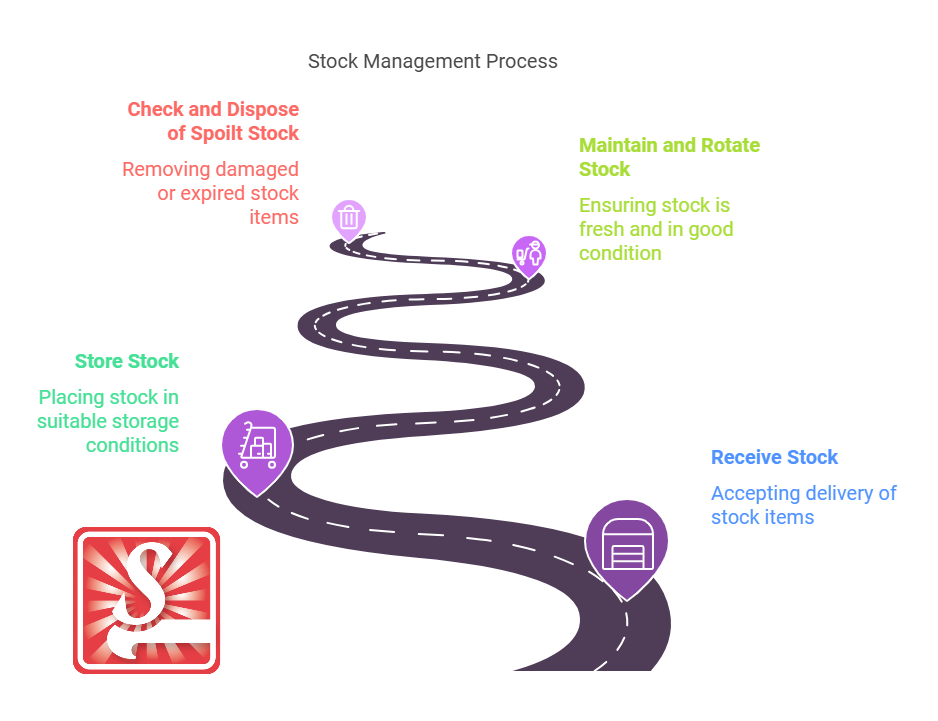

Managing damaged items when receiving, storing, and maintaining stock involves processes to identify, document, and address items that are not in optimal condition. It encompasses systematic inspection, reporting protocols, and the implementation of appropriate solutions, ensuring the integrity and availability of stock for operations.

Why do people in enterprises need to manage damaged items when receiving, storing, and maintaining stock?

Enterprises must manage damaged items efficiently to maintain the quality and consistency of their stock, which directly affects customer satisfaction and business reputation. Addressing damages promptly prevents potential losses and operational disruptions, ensuring smooth supply chain management and enhancing financial performance.

“Effective management of damaged stock is crucial for maintaining quality control, reducing waste, and protecting the core operations of the business.”

What are the key components or elements of managing damaged items in stock?

Key components include:

- Inspection: Regular checks during the receiving and storage stages to identify damages.

- Documentation: Recording details of damaged items for tracking and resolution.

- Communication: Reporting to vendors or suppliers and internal teams promptly.

- Corrective Actions: Implementing strategies to minimize recurrence and manage existing damages.

- Improved Packaging and Handling: Enhancing procedures to prevent future damage.

What key terms, with descriptions, relate to managing damaged items in stock?

- Inspection Protocol: Set procedures for checking and assessing stock condition.

- Damage Report: A documented record detailing the nature and extent of damage observed.

- Return Process: Method of sending back damaged goods to suppliers.

- Preventive Measures: Steps taken to avoid future damage to items.

- Stock Reconciliation: The process of verifying physical stock matches recorded quantities.

Who is typically engaged with operating or implementing the management of damaged items in stock?

Warehouse managers, inventory controllers, procurement officers, and quality assurance staff are primarily engaged in managing damaged items. These roles are responsible for ensuring that all stock items meet the required standards and any damage is handled efficiently.

How does managing damaged items in stock align or integrate with other components of Hospitality and Catering?

Managing damaged items in stock aligns with inventory management and supply chain efficiency in hospitality and catering. It ensures that only quality goods are served to customers, minimizing waste and enhancing the overall guest experience. Proper integration ensures comprehensive stock control and availability.

Where can the student go to find out more information about managing damaged items in stock?

What job roles would be knowledgeable about managing damaged items in stock?

Roles include:

- Warehouse Managers

- Inventory Controllers

- Quality Assurance Officers

- Procurement Officers

- Supply Chain Coordinators

What is managing damaged items in stock like in relation to sports, family, or schools?

Managing damaged items is like a sports team dealing with an injured player — quick assessment, effective communication, and strategic adjustment ensure the team keeps performing. In a family, it resembles fixing a household issue to maintain harmony. In schools, it mirrors addressing student needs to ensure learning proceeds smoothly despite challenges.

(The first edition of this post was generated by AI to provide affordable education and insights to a learner-hungry world. The author will edit, endorse, and update it with additional rich learning content.)

Post Tagged with

Post Tagged with