Understanding the Importance of Material Lists in Basic Estimation and Costing

Posted by SkillMaker in Jan, 2025

What is a concise description of a material list in basic estimation and costing?

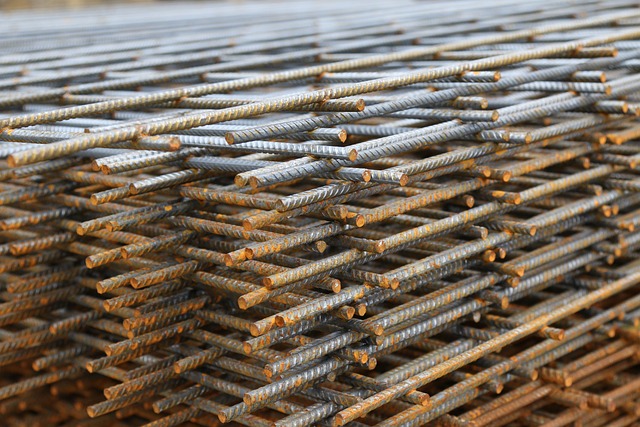

A material list is a comprehensive inventory of all materials and items required for a construction project, detailing types, quantities, and specifications. It’s a vital component in basic estimation and costing, helping to ensure accurate budgeting, procurement, and resource allocation.

Why do people in enterprises need a material list for basic estimation and costing?

Enterprises need a material list to ensure a structured and well-organised approach to project planning and budgeting. Without it, projects can face delays, increased costs, or wasted resources due to improper allocation and procurement. Material lists provide clarity and precision, supporting efficient cash flow management and minimising financial risks.

“A comprehensive material list is the backbone of construction estimation, ensuring accuracy, efficiency, and cost control.”

What are the key components or elements of a material list in basic estimation and costing?

Key components of a material list include:

- Item Description: Detailed information about each material, including size, type, and quality.

- Quantity Required: Accurate measurement of how much of each material is needed.

- Unit Costs: Price of materials per specified unit.

- Total Cost: Calculation of the total expense for each material type.

- Supplier Information: Details of where the materials will be sourced from, including reliability and pricing options.

What key terms, with descriptions, relate to the material list in basic estimation and costing?

Registered Trademark®

- Bill of Quantities (BoQ): A detailed breakdown of work components required for the construction project.

- Take-off List: A key document for measuring materials and estimating costs accurately.

- Cost Forecasting: The process of predicting future costs based on historical data and market trends.

- Materials Variance: The difference between projected and actual materials usage or pricing.

Who is typically engaged with operating or implementing a material list in basic estimation and costing?

Quantity surveyors, estimators, project managers, and procurement officers are typically responsible for creating and managing the material list. These professionals ensure the accuracy, thoroughness, and practical application of the list throughout the project lifecycle.

How does a material list integrate with other components of Construction in Australia?

The material list integrates closely with project scheduling, cost control, risk management, and resource planning in construction. Accurate material lists help align procurement timelines with project milestones and mitigate risks related to supply chain disruptions. They also work with costing models to keep financial execution on track.

Where can the student go to find out more information about material lists in basic estimation and costing?

What job roles would be knowledgeable about material lists in basic estimation and costing?

Roles include:

- Quantity Surveyors

- Estimators

- Project Managers

- Procurement Officers

- Construction Managers

What is the material list like in relation to sports, family, or schools?

A material list in construction is similar to a shopping list used by a sports team, family, or school. For a sports team, it’s akin to planning for equipment required for a tournament. Within a family, it resembles a weekly grocery shopping list, detailing everything needed for household meals. In schools, it’s like a syllabus list for the school year, ensuring every educational requirement is planned and accounted for.

(The first edition of this post was generated by AI to provide affordable education and insights to a learner-hungry world. The author will edit, endorse, and update it with additional rich learning content.)

Post Tagged with

Post Tagged with