Temperature Checks: Ensuring Optimal Stock Management

Posted by SkillMaker in Jan, 2025

What is a concise description of temperature checks when receiving, storing, and maintaining stock?

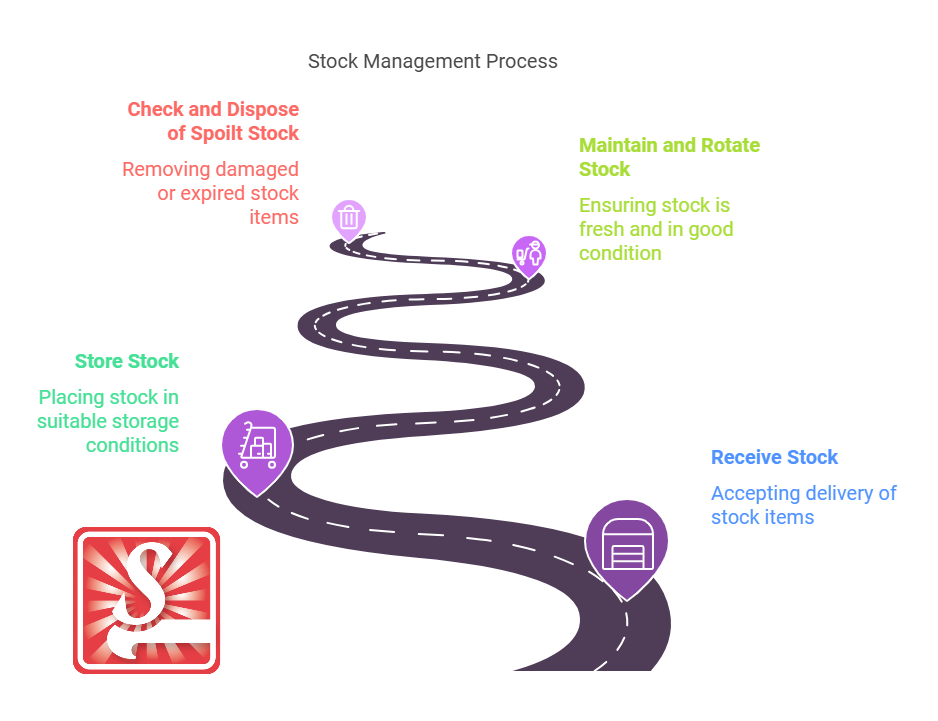

Temperature checks when receiving, storing, and maintaining stock involve systematically monitoring the temperature of perishable goods to ensure they are kept within safe limits. This is essential to prevent spoilage, maintain quality, and comply with food safety standards in the hospitality and catering industry.

Why do people in enterprises need temperature checks when receiving, storing, and maintaining stock?

In enterprises, temperature checks are crucial for ensuring the integrity and safety of perishable goods. They prevent the risk of foodborne illnesses, reduce wastage, and maintain the quality of products. This adherence to safe temperature ranges is vital for regulatory compliance and to uphold the reputation of the business.

“Consistently monitoring temperatures is key to ensuring food safety and quality in hospitality operations, safeguarding both consumers and the business.”

What are the key components or elements of temperature checks for stock management?

Key components of effective temperature checks include:

- Thermometers: Accurate devices for measuring temperatures.

- Regular Monitoring: Consistent checks at scheduled intervals.

- Record Keeping: Documentation of temperature readings.

- Corrective Actions: Procedures to follow if temperatures deviate from safe ranges.

- Training: Ensuring staff are equipped to perform accurate checks.

What key terms, with descriptions, relate to temperature checks in stock management?

Registered Trademark®

- Danger Zone: Temperature range in which bacteria grow rapidly (usually between 5°C to 60°C).

- Critical Control Point: A step where control can be applied to prevent or eliminate a food safety hazard.

- Calibration: Ensuring thermometers are providing accurate readings.

- Ambient Temperature: The surrounding environmental temperature.

- Cold Chain: A temperature-controlled supply chain to ensure cold products remain chilled from production to consumption.

Who is typically engaged with operating temperature checks in stock management?

Typically, receiving clerks, storeroom staff, kitchen supervisors, and quality control personnel are responsible for conducting temperature checks. Their role is to ensure that temperatures are monitored and recorded, and that appropriate measures are taken to maintain product integrity.

How do temperature checks integrate with other components of Hospitality and Catering?

Temperature checks are integral in ensuring that food safety standards are met, which is essential in food preparation and service. They align with hygiene protocols, stock rotation systems, and food storage practices to create a holistic approach to food safety and quality assurance.

Where can the student go to find out more information about temperature checks in stock management?

- Food Standards Australia New Zealand

- SafeFood Production Queensland

- Australian Government Department of Health

What job roles would be knowledgeable about temperature checks in stock management?

Roles include:

- Stock Controllers

- Quality Assurance Officers

- Kitchen Managers

- Food Safety Inspectors

- Warehouse Supervisors

What are temperature checks in stock management like in relation to sports, family, or schools?

In sports, temperature checks are comparable to monitoring an athlete’s vitals to ensure peak performance and prevent injury.

In a family context, they resemble keeping a consistent routine to maintain a healthy household environment.

In schools, they reflect adhering to a strict timetable to ensure the smooth running of daily operations, ensuring everything functions optimally.

(The first edition of this post was generated by AI to provide affordable education and insights to a learner-hungry world. The author will edit, endorse, and update it with additional rich learning content.)

Post Tagged with

Post Tagged with