Managing Incoming Stock: Essential Details in Receiving, Storing, and Maintaining

Posted by SkillMaker in Jan, 2025

What is a concise description of managing incoming stock details?

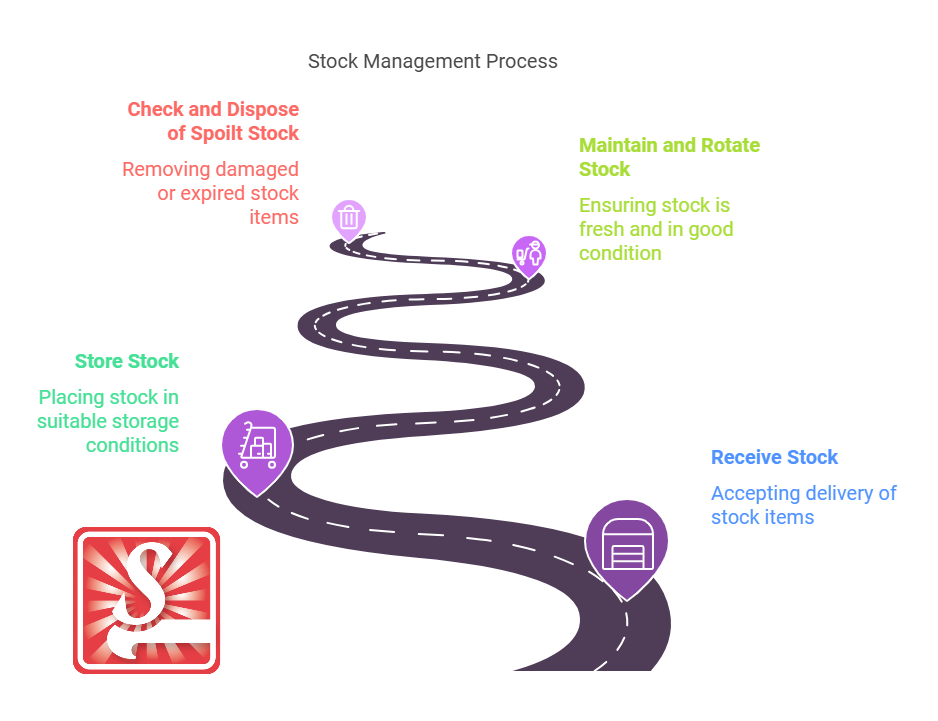

Managing incoming stock details refers to the systematic approach of receiving, verifying, and recording new stock arrivals in a hospitality or catering business. It involves ensuring that the correct items are delivered, quantities are accurate, quality meets company standards, and the goods are appropriately stored to maintain freshness and usability.

Why do people in enterprises need to manage incoming stock details?

Effective management of incoming stock details is crucial for maintaining supply chain efficiency, minimising waste, and ensuring that a business has the necessary resources to meet customer demand. It helps in tracking inventory levels accurately, preventing overstocking or running out of essential items, and upholding quality standards, ultimately leading to enhanced customer satisfaction and cost efficiency.

“Managing incoming stock effectively ensures a balanced inventory, reduces waste, and guarantees quality, driving success in hospitality and catering operations.”

What are the key components or elements of managing incoming stock details?

Key components of managing incoming stock details include:

- Verification: Checking the delivery against purchase orders.

- Quality Control: Inspecting goods for damage, spoilage, or discrepancies.

- Documentation: Accurate recording of stock received.

- Storage: Proper storage strategies to maintain quality.

- Security: Controls to prevent theft or loss.

What key terms, with descriptions, relate to managing incoming stock details?

Registered Trademark®

- Purchase Order (PO): A document issued by a buyer to a seller, indicating types, quantities, and agreed prices for products or services.

- Delivery Docket: A document that accompanies a shipment of goods, providing details about the shipment.

- Stocktake: A process of verifying and recording the current level of stock held in storage.

- FIFO (First In, First Out): A method of stock rotation and management.

- Inventory Management System: Software used to track stock levels, orders, sales, and deliveries.

Who is typically engaged with operating or implementing incoming stock details?

Staff responsible for managing incoming stock details generally includes stock controllers, warehouse managers, chefs, sous chefs, and procurement officers. Storepersons and those involved in inventory logistics also play an essential role, ensuring that stock meets quality standards and is suitably stored and managed within the enterprise.

How does managing incoming stock details align or integrate with other components of Hospitality and Catering?

Managing incoming stock details is foundational in hospitality and catering, supporting food preparation, service quality, and operational efficiency. It’s integrated with inventory management, procurement processes, quality assurance, and customer service strategies, ensuring that the different elements of a business work harmoniously together to deliver exceptional customer experiences.

Where can the student go to find out more information about managing incoming stock details?

What job roles would be knowledgeable about managing incoming stock details?

Roles include:

- Stock Controllers

- Warehouse Managers

- Chefs and Sous Chefs

- Procurement Officers

- Inventory Managers

What is managing incoming stock details like in relation to sports, family or schools?

In relation to sports, managing incoming stock details is like ensuring that a team has all the necessary equipment and resources to train and compete effectively, accurately accounting for each resource. In a family context, it mirrors grocery shopping and meal planning to have a balanced diet and necessary items in the household. Regarding schools, it reflects the careful management of educational materials and resources to support teachers and student learning consistently.

(The first edition of this post was generated by AI to provide affordable education and insights to a learner-hungry world. The author will edit, endorse, and update it with additional rich learning content.)

Post Tagged with

Post Tagged with